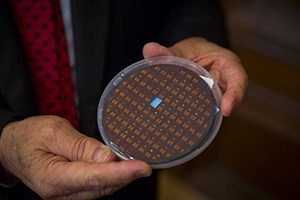

A graphene-based water sensor developed at the University of Wisconsin-Milwaukee outperforms current technologies for sensing speed, accuracy and sensitivity – exactly what’s needed to continuously monitor drinking water for miniscule traces of contaminants like lead.

But the cost of mass-producing these tiny sensors using traditional methods is high.

The National Science Foundation has recently awarded UWM scientists $1.5 million to perfect a low-cost manufacturing alternative that will also scale up production: inkjet printing.

The grant will help researchers engineer the ink, which will contain the nanomaterials that give the sensors their capabilities. The ink is then layered on top of the sensors’ plastic substrate the way inkjet printers deposit ink on paper.

The project is led by Deyang Qu, UWM’s Johnson Controls endowed professor, in collaboration with Northwestern University and UW-Madison.

While printing with graphene, a conductor, has been demonstrated successfully, printing with graphene oxide, a semiconductor, has been less studied, said Junhong Chen, UWM distinguished professor of mechanical engineering, who developed the sensor platform.

Because the two materials exhibit different properties, engineering the ink containing graphene oxide and various chemical probes will require some fine-tuning, said Chen.

In addition to engineering inks containing various materials, the researchers will have to integrate components at different scales.

The performance of the printed sensors will be tested by companies, including the startup NanoAffix Science LLC, founded by Chen. The results may be applicable to cost-effective manufacturing of other printable, flexible electronics such as solar cells, lithium-ion batteries and supercapacitors.