Best Senior Design Projects

One winning team from each department was recognized at the Order of the Engineer ceremony on Saturday, May 18, 2024.

Winners will receive a 20 ounce 100% stainless steel Otterbox Elevation Tumbler compliments of GE HealthCare and the College of Engineering & Applied Science.

Click on each project below to see objective, team members, advisor(s), and presentation dates/times.

Program Sponsor

Biomedical Engineering

Presentations: Tuesday, May 7 from 1-3 pm in EMS 250

Guardian Cradle

Objective: To create a portable device capable of surveying infant safety by monitoring environmental conditions. Develop a UI to alert caregivers of potential danger.

Team Members:

- Kaley Blake

- Brianna Geurts

- Nate Griepentrog

- Samuel Hauke

Advisors:

- Jacob Rammer, Assistant Professor Biomedical Engineering

- Grace Fasipe, Biomedical Engineering

Presentation: Tuesday, May 7 from 1-3 pm in EMS 250

Link to PowerPoint Presentation

Project Findings:

For the duration of the senior design course, our team has developed an innovative solution to infant monitoring, specifically in the automobile.

The Guardian Cradle is a portable device that includes a variety of sensor modalities. This project has tested our ability to design circuits, device casing, and software required to make a product from the ground up.

Each year we see the unexpected loss of many infants due to heatstroke. Our device aims to warn parents of environmental threats related to temperature, air quality, and noise level. A priority of our team was to develop a monitoring device that was not a hassle to use. Our prototype is relatively small and capable of attachment to a wide-variety of infant cradles and carriers. When unsafe environmental conditions are detected by the device, a signal is sent to the users mobile device. We believe this product is unique from preexisting devices and has potential to compete in the baby-monitoring market.

Giggly Gears Prosthetics

Objective: To design an electronically controlled below-the-knee leg prosthetic that is extendable for children between the ages of 5-8 years old. The product will be 3D printed and controlled via EMG sensors.

Team Members:

- Walaa Alhammad

- Corey Huffman

- Seth Kornelsen

- Julie Sandria

- Adam Schultz

Advisors:

- Jacob Rammer, Assistant Professor Biomedical Engineering

- Grace Fasipe, Biomedical Engineering

Presentation: Tuesday, May 7 from 1-3 pm in EMS 250

Link to PowerPoint Presentation

Project Findings:

For the transtibial prostheses, two types of testing were conducted: digital simulations in Fusion 360 for both static and dynamic forces on the ankle joint, and physical compression and weathering tests. Fusion 360 simulations used PLA and ASA materials. The results from the static testing suggest that both materials are equivalent in nature, but ASA has a much higher safety factor. Dynamic testing provided some problems with the results suggesting that PLA is a much stronger material than ASA. This could potentially have to do with the inaccuracies in the printable materials library that was used.

When performing the compression testing, again PLA and ASA materials were observed for the prosthetic. The foot with the spring was connected with bolts to the ankle joint and was tested using the MTS 3.3-kip Axial Test Machine. The ASA proved to be the superior material and was able to bear 500 pound-forces more than the PLA version.

Weathering is being conducted currently.

The results suggest that ASA is a much better material for the application that will be used. When the prosthetic is adjusted to it’s lowest setting it is at its strongest under physical load. If given more time, an electrical system could be implemented into the prosthetic to give it motorized movements.

Civil & Environmental Engineering

Presentations: TBD

414 Engineering

Objective: The goal is to redesign and improve Lake Dr. from E Kensington Blvd to E Edgewood Ave while accommodating pedestrians and bicyclists and their safety, and also providing adequate parking.

Team Members:

- Kyle Brahm

- Andrew Innerbner

- Grace Mayes

- Will Poellot

- Nathan Samuelson

Advisors: Sarah Blackowski and Clayton Cloutier, Civil & Environmental Engineering

Fresh Coast Engineering

Objective: The goal is to redesign a 1.3 mile strip of N. Lake Drive. The minor arterial has been described as dangerous for pedestrians and cyclists and our design promotes pedestrian safety as well as local travel.

Team Members:

- Sophia Governatori

- Patrick McSorley

- Adrien Prange

- Benas Urbietis

Advisors: Sarah Blackowski and Clayton Cloutier, Civil & Environmental Engineering

Premier Engineering

Objective: The goal is to redesign a 1.3 mile segment of Wisconsin 32 Lake Drive including an Atwater Park addition with the focus on upgrading the community’s infrastructure.

Team Members:

- Ashley Drzewiecki

- Byron Edwards

- Michael Goulder

- Cayla Robinson

- Orlando Shelton Blake

Advisor: Sarah Blackowski, Civil & Environmental Engineering

JAMS Engineering

Objective: The goal is redesign the stretch of Lake Drive between Kensington and Edgewood to accommodate better transportation for bikers and pedestrians in addition to providing an appropriate amount of parking.

Team Members:

- Angel De Jesus Ortiz

- John Kelliher

- Josh Kosky

- Shriya Mehrotra

Advisors: Clayton Cloutier and Sarah Blackowski, Civil & Environmental Engineering

Industry Mentor: Tim Anheuser, Kapur Inc.

NRT Engineering

Objective: The new proposed WIS 32 consists of a roadway with pedestrians and bicyclists in mind. The project would include pavement rehabilitation of a four-lane roadway.

Team Members:

- Thomas Johnson

- Nash Rettler

- Ruben Zavala

Advisors: Sarah Blackowski and Clayton Cloutier, Civil & Environmental Engineering

Computer Science

Fitness Progress Tracker

Objective: The goal is to develop a user-centric fitness app using cutting-edge tech to address market gaps, foster community engagement, and promote wellness worldwide.

Team Members:

- Michael Terrence Constable

- Jacob Ryan Hanson

- Soham Nandi

- Phani Ram Teja Ravipati

- Zachary James Walensa

Advisor: Avinash Rajendra, Computer Science

Restaurant Server Scheduler

Objective: The goal is to design a web-based application that can be used by restaurants as an in-house organizational tool.

Team Members:

- Amna Ataullah

- Anna Fronk

- Jose Rodriguez

- Maram Saleh

- Hudson See

- Demi Urive

Advisor: Avinash Rajendra, Computer Science

Electrical Engineering

Presentations: Friday, May 10 in E250 & E237

Faze Wireless Headphones

Objective: To create a new design of wireless, rechargeable, headphones with mobile application attachment capable of adjusting individual audio settings such as EQ, bass, treble, and compression.

Team Members:

- Ahmed Ataullah

- Dimitrije Jovanovich

- Andrew Rich

- Tyler Swenson

- Patrick Whalen

Advisor: Jeff Kautzer and William Dussault, UWM CEAS Electrical Engineering

Presentations: Friday, May 10 in E250 & E237

Major Features:

- Voltage range is 0-10 V

- Frequency range is 0 to 500 kHz

- Battery capacity of more than 8000mAh

Intended Market:

- US market

Cost:

- Sales Price: $400, Component Cost: $30, Assembly & Test Costs: $50

Environment:

- Indoor, Outdoor, Wearable

- Operating Temp Range: 0 to 70 C

- Humidity Range: 100% Max

Power Input:

- AC Power: 120 VAC

- Battery Power: 8.4V

Major Functions:

- Modes: On, Off, Standby, Sleep

Major Interfaces, User Controls & Displays:

- Smart Phone App

Portable LCR Meter

Objective: To design a portable and rechargeable LCR meter that can measure inductance, capacitance and resistance with an accuracy of 0.2%.

Team Members:

- John Mark De Guzman

- Joshua Nathaniel

- Touxai Xiong

- Alexander Yang

Advisor: Jeff Kautzer and William Dussault, UWM CEAS Electrical Engineering

Presentations: Friday, May 10 in E250 & E237

Major Features:

- Measures 1 time constant in a simple RC or RL circuit (parallel)

- Measures the voltage across a test resistor to find the resistor value being measured

- Operates on a (2 cell) 3.7V Lithium-ion battery with a battery life of 7.5 hrs on a single charge

Intended Market:

- US market

Costs:

- Sales Price: $600

- Materials Cost: $130

- Assembly, Test & MFG Costs: $30

- Development Cost: $560,000

- Labor: $150/hour

Environment:

- Indoors or outdoors (dry conditions)

- Operating Temp Range: (-10 to 55°)

- Operating Humidity Range: (0%-100%)

Power Input:

- Battery Power: ( 2 Cell) 3.7V @ 2.6 Ah

Major Functions:

- Rechargeable battery unit with up to 7.5 hours of battery life

- Manually measures and displays values of LCR

- Min Resistance range of 100 Ω to 10 kΩ

- Min Capacitance range of 20 nF to 20 µF

- Min Inductance range of 20 µH to 20 mH

- Basic accuracy of 0.2%

- Indication of a low battery of the LCR meter

Major Interfaces, User Controls & Displays:

- Smart Phone App

Power Quality Immunity Test Generator

Objective: To design a single-phase power testing system that simulates AC drop-out and brown-out periods and mimics the IEC-61000-4-11 Class III testing modes.

Team Members:

- Belle Dionido

- Alyssa Frisch

- Alexander Gersch

- Riley Krueger

- Tyler Vincent

Advisor: Jeff Kautzer and William Dussault, UWM CEAS Electrical Engineering

Industry Mentor: Balaji Sankarshanan, GE HealthCare

Presentations: Friday, May 10 in E250 & E237

Major Features:

- Single Event Manual Injection Buttons for 40%, 70% and 80% dip and 100% dropout

- Mimic IEC61000-4-11 Single Phase Class III Testing Modes

Intended Market:

- US market

Cost:

- Sales Price: $5,000, Component Cost: $2,100, Assembly & Test Costs: $200

Environment:

- Indoor

- Operating Temp Range: 15 C to 35 C

- Operating Humidity Range: (10% to 85% Non-Condensing)

Power Input:

- Residential AC Power: min 108CAC – max 132VAC @ 10 Amps Max

Major Functions:

- Temperature and Humidity Display

- Single Event Manual Injection Buttons for 40%, 70%, and 80% dip and 100% drop out

- Zero Cross Switching to minimize inrush loading

- Over-current protection for Load, Full Isolation from AC Mains Power

- Low Noise – complete linear technology using Step Down Transformer

- Repeat Cyclic Mode with Programmable Sequencing

Wireless Guitar Amplifier

Objective: To design of a portable, battery-powered, solid-state, electric guitar amplifier with a wireless instrument plugin and onboard pre-amp.

Team Members:

- Ali Alshakhs

- Sean Benet

- Kanwar Chawla

- Erik Erlandson

- Dylan Statler

Advisors: Jeff Kautzer and William Dussault, UWM CEAS Electrical Engineering

Presentations: Friday, May 10 in E250 & E237

Major Features:

- 1 x 6.5″ midrange 8Ω loudspeaker

- Power amplification stage with 5W peak output

- Analog low, mid, treble, and gain adjustment knobs for tone shaping

- Wireless 1/4″ jack instrument adaptor unit with onboard preamp and Bluetooth communication

Key Differentiating Performances:

- Completely cable-free operation

- Signal-to-noise ratio of 85+ SNRdb

- Up to 10-meter range

Cost:

- Sales Price: $300, Component Cost: $200, Assembly & Test Costs: $25

Environment:

- Mobile, can be used indoors and outdoors. Ingress protection.

Power Inputs:

- Amplifier and Adapter: Battery Power, rechargeable

Major Functions:

- 24-bit ADC for Bluetooth transmission of guitar signal, 24-bit Audio Output

- 85 dB signal-to-noise ratio; Full audio range bandwidth

- EQ, Volume, Gain

- Amplifier output: 5 Watts Max

Industrial Engineering

Contractor Route & Fleet Optimization

Objective: The goal of this project is to develop a methodology to get the optimum number of routes for FedEx Ground contractors, and use this routing methodology to determine the optimal truck fleet makeup (truck types) and employee requirements.

Team Members:

- Bandar Alharbi

- Mohammad Altuwaijri

- Wyatt Graczkowski

- Raul Medina Castello

Project Advisor:

- Matthew Petering, Industrial Engineering

Industry Mentor:

- Jugal Pandya, FedEx

Project Presentation:

TBD

Connected Systems Institute

(East of Golda Meir Library)

Facility Layout

Objective: The project goal is to provide an improved layout for the Keeper Goal facility based on factors such as distance between machines, WIP storage, and 6S.

Team Members:

- Mason Leedle

- Kat Van Booven

Project Advisor: Iftekharuddin Khan, Industrial & Manufacturing Engineering

Industry Mentor: Adam Fink, Keeper Goals

Project Findings:

TBD

Materials Science & Engineering

Presentations: Thursday, May 9 from 11 am – ~12:30 pm in EMS W119

Analysis of Organic Inhibitors on Galvanic Corrosion: Experimental and In-silico Approach

Team Members:

- Ruba Almuallem

- Jonathan Koene

- Kyung Lee

Faculty Advisors:

- Dr. Ben Church, Associate Professor, Materials Science and Engineering

- Phani Nunna, Materials Science & Engineering

Industry Mentor: Daniel Kaminski, Rockwell Automation

Cast White Iron Heat Treatment

Objective: The goal of our project is to improve the life of a component through improvements in the heat treatment process.

Team Members:

- Jordan Fuller

- Pranav Roy

- Michael Wilke

Faculty Advisor: Dr. Ben Church, Associate Professor, Materials Science and Engineering

Industry Mentor: Paul Meyer, Industrial Associates

Digital Image Analysis of Steel Microstructure

Objective: Identify phase transformation temperature in various grades of steel and create a predictive formula that will allow the identification of transition temperature for untested grades.

Team Members:

- Matt Utter

- Elijah Etten

Faculty Advisor: Dr. Ben Church, Associate Professor, Materials Science and Engineering

Industry Mentor: Ted Fitzpatrick, Process Metallurgist, Charter Steel

Bond Strength of Metal-Matrix Composite Insert Casting

Objective: Design a test method to measure the mechanical bond strength between a metal-matrix composite (MMC) and aluminum for an insert casting process.

Team Members:

- Pong Lee

- Gavin Schmer

- James Veltri

- Steven Wenninger

Faculty Advisor: Dr. Ben Church, Associate Professor, Materials Science and Engineering

Industry Mentor: David Weiss, VP Research and Development, Eck Industries

Safe Passivation of a Pyrophoric Powder

Objective: Design a process that allows for safe, controlled passivation of pyrophoric aluminum metal powder by forming an outer layer of aluminum oxide.

Team Members:

- Chloe Hotze

- Luis-Agustin Moctezuma

- Katelyn Sprandel

Faculty Advisor: Dr. Ben Church, Associate Professor, Materials Science and Engineering

Industry Mentor: Dr. Ben Schultz, Manager, Alloys and Composites, MATSYS, Inc.

Mechanical Engineering

Presentations: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

3D Parts Cleaner

Objective: The goal of the project is the make a device that washes and cleans the resin off of the 3D parts that are built in the ‘figure 4 modular 3D printing system’.

Team Members:

- Jacob Ford

- Josh Olson

- Chayank Pawar

- Parker Stelter

- Ian Sobojinski

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Jordan Nowak, Engman-Taylor

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

The team was supposed to make a prototype that cleans resin from 3D printed parts from a figure 4 modular printer. We were successful in creating a prototype with CAD files and all the supplemental documents needed to prove our findings.

Cabin Heat Exchanger

Objective: The goal of this project is to design a cabin heating system that fits the Cirrus SR20 plane. It will heat the cabin interior to comfortable temperatures during high-altitude flights.

Team Members:

- Richard Bennett

- Joshua Estell

- Halah Idrissi

- Andrew Oja

- Shawn Roscoe

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Joe Delany, DeltaHawk Engines, Inc.

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

This senior design project worked with the company DeltaHawk Engines, Inc. to design a heating system for their test aircraft, a Cirrus SR20. The design of the system uses the coolant from the plane’s engine inside a heat exchanger to heat the cabin of the plane. Currently, the heating system in place uses an electrical heater, but this solution creates a concentrated heat on the pilot and is not diffused across the cabin.

The solution created over the duration of this project was mounting a heat exchanger to the plane’s firewall. S-CAT tubing was used to connect the heat exchanger to the plane’s air intake and output heated air into the cabin. Inside the plane’s air intake, an air scoop is used to provide sufficient airflow to the system and provide air to the heat exchanger, which is then directed to the cabin at 80˚F. The air output into the cabin has a diverter box attached and is able to direct the pilot’s desired amount of air into the cabin while rejecting the rest outside.

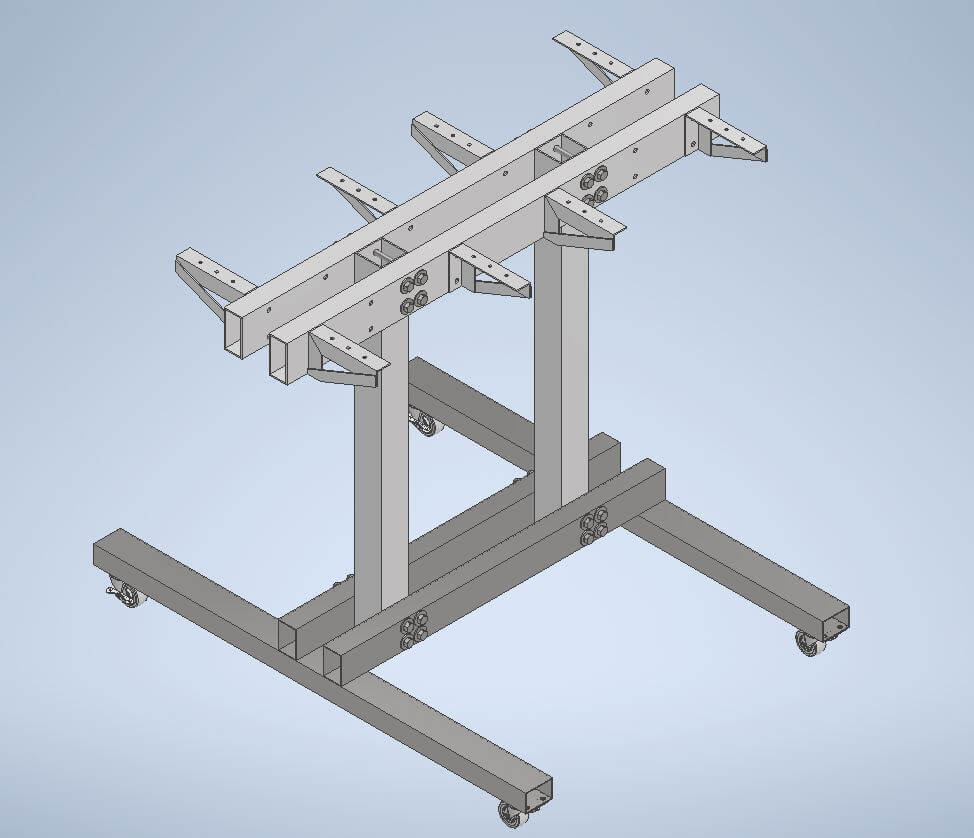

Cap Sealer Material Handling System

Objective: The project goal is to design a cap sealer handling system that reduces the amount of current team lifts during the manufacturing process of the cap sealers.

Team Members:

- Cameron Abbey

- Matthew Deacon

- Frank Lauerman

- Benjamin Olson

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Nate Ryan, Enercon Industries Corporation

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

The time and engineering efforts put forth by this team proved to be successful. The team delivered Enercon a final design that, once constructed, will satisfy all agreed upon CTQs. Upon completion of this project, with no physical prototype, 2 of the 5 CTQs were able to be confirmed, those being:

- Utilize at least 75% “Off-the-Shelf” parts to reduce the complexity of manufacturing.

- The solution must achieve a target manufacturing cost of less than or equal to 400 dollars per unit. (The final total of $430.73 was approved by the Sponsor)

The three remaining CTQs below will be tested for satisfaction by Enercon to prove the overall success of the submitted design:

- Create a design capable of carrying 4 “Touch” cap sealers or 2 “Max” cap sealers.

- The design must be capable of withstanding ambient temperatures of 45°C to 50°C for 4 hours, with the occasional chance that the cap sealer is left overnight in the chamber for 13 hours.

- Reduce the number of required manual lifts of the cap sealers to less than or equal to 3.

While the three CTQs above were confirmed via analytical methods and CAD simulations, physical demonstration of these is still required. However, given the team’s knowledge of and familiarity with the problem at hand, the team believes that delivered design will meet and exceed all requirements set by Enercon.

Clarifier Panel System

Objective: The project goal is to design a panel mechanism that absorbs forces acting on the center well of clarifiers that experience seismic events while maintaining the efficient operation of the clarifier.

Team Members:

- Kellen Johnson

- Payton Leonardelli

- Hannah Schroeder

- Kevin Tong

- Grant Woodruff

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Allen Lepak, Zylem

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

Xylem, a water solution and water technology company, provides innovative water solutions through smart technology. One of the many services Xylem provides is water clarifiers. Current water clarifiers use a large steel center well structure to help ease sediment flow to the bottom of the clarifier. Due to seismic activity in places like California and Georgia, waves are crashing into the center, causing damage to the support structures. Xylem designed a solution to this by using breakaway panels when the waves make contact, but due to UV and other varying factors, the panels popped out without any force on them.

After talking to Xylem, we created a list of necessary or critical-to-quality items that our solution had to follow. These consisted of having the panel density > 997kg/cm^3, able to break away in both directions, breaking away at 8-10lbf applied to the center of the panel, and a prototyping budget < $1000. This team was able to meet all those requirements and complete the goal they were tasked with.

Fabrication Fixture System

Objective: The project goal is to produce a fixture system that can assist in the manufacturing of components for zero-turn electric motors.

Team Members:

- Kyle Ihrke

- Mason Ihrke

- Jeremy Oommen

- Carolyn Scharnick

- Felix Woehl

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Richard Rapant, Industrial Engineer, Generac

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

After careful consideration, the team has concluded that Design 1 stands out as the optimal option for addressing Generac’s welding fixture requirements, primarily due to its remarkable compatibility with components and efficient manufacturing process. Aligned precisely with Generac’s specifications, this design facilitates the simultaneous clamping of four components onto the welding table by utilizing a grid table equipped with push clamps and support blocks. Moreover, through the integration of essential elements from competing systems, the team has enhanced the effectiveness and adaptability of the chosen framework.

It is recommended to utilize all three idle robotic welding cells simultaneously to maximize production capacity and develop additional fixture designs to accommodate potential production variations. Additionally, it is advised that all parts be made of machined aluminum, except for ASM07_ASSIST_ARM_BLOCK, which should be manufactured using metal 3D printing or pressure casting. Implementation of these recommendations promises to maintain Generac’s competitive edge in the lawnmower market while further enhancing production efficiency.

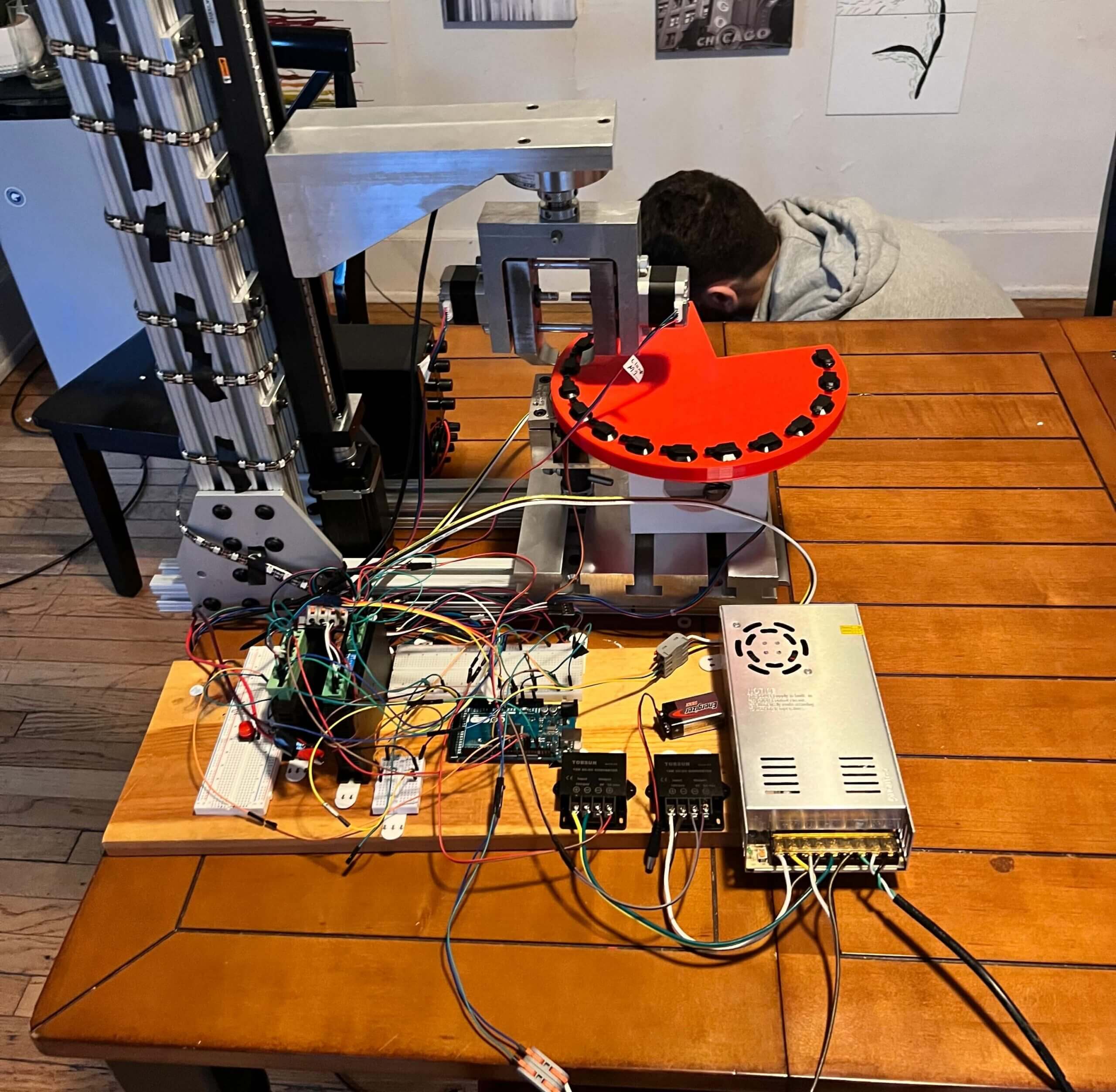

Autoloader for Fir Tree Mechanical Testing

Objective: The project goal is to automate the Fir Tree testing process so a person can load up a batch of parts, push go, and the tester will cycle through all the parts.

Team Members:

- Brennen Beck

- Rajab Elsharef

- Zachary Herbert

- Jacob Weber

- Isaac Wolf

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Joey Friedli, Hellermann Tyton

Project Findings:

HellermannTyton manufactures and supplies products for fastening, fixing, identifying, and protecting cables and their components, ensuring high quality through rigorous testing procedures. Our group was tasked with automating the manual tensile testing process to handle sixteen parts per batch, meeting five critical-to-quality (CTQ) requirements established with our sponsor:

- Handling loads up to 150lbf during testing.

- Prototyping budget under $1000.

- Incorporating visible and audible status signals.

- Ensuring Fir Tree slot alignment within 2 degrees.

- Ejecting parts at least 30mm away from the testing hole after testing.

We successfully completed the project within the deadline, meeting all CTQs. To achieve this:

- We conducted FEA and verified material selection, achieving a force of 237.36lbf with no visible deformation.

- Our budget remained under $600, utilizing school resources like the machine shop.

- Implemented LED lights and a buzzer audible at 15 feet.

- Designed the board to ensure Fir Tree slot alignment within 2 degrees.

- Designed the board to eject parts at least 50mm away from the testing hole, exceeding the 30mm requirement.

- Through thorough design, testing, and verification processes, we achieved our project goals effectively.

Folding Aluminum Goal Improvement

Objective: The project goal is to address the most common VOC issues with Keeper Goals’s folding aluminum soccer goals. Specifically, these issues stem from the center support bars currently used.

Team Members:

- Megan Andresek

- Clara Broecker

- Zachary McFarland

- Jenna Van Hoogstraten

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentor: Adam Fink, Keeper Goals

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

TBD

Universal Nest Fixture

Objective: The project goal is to create a universal tool stand so Hellermann Tyton can test their competitors’ tools as well as their own.

Team Members:

- Shpejtim Avidiu

- Brett Baumann

- Graden Gibson

- Yousef Zahran

Project Advisor: Mohamed Yahiaoui, Senior Lecturer Mechanical Engineering

Industry Mentors: Aaron Sherman and Ryley Walter, Hellermann Tyton

Project Presentation: Wednesday, May 1 from 8:15 am – 2:00 pm in EMS E250

Project Findings:

The team gained valuable insights into planning, executing, and delivering a product meeting HellermannTyton’s requirements. They emphasized the need for thorough testing to ensure all functional requirements are met and for evaluating tools from both geometric and functional perspectives. Better communication through asking comprehensive questions could have improved decision-making clarity. They suggested future classes be extended to two semesters and include electrical and/or software engineering students for a more comprehensive team.

The project, though mostly successful in meeting critical-to-quality (CTQ) criteria, could be improved with some adjustments. Firstly, enhancing the depth of the handle driver area to ensure compatibility with all manual application tools. This might necessitate additional profiles to match various handle end shapes. For the C-Bracket, reducing the span would enhance rigidity, and widening it with an extra screw hole would increase versatility. A “vice” style translation could be considered. The Cam’s function seems redundant, so it could be omitted. Establishing a detailed coordinate system for testing tools is recommended. Using PLA for the alignment tool, wedge, and potentially the Cam could be beneficial as they aren’t subjected to high stress.