The Prototyping Center

The UWM Prototyping Center is home to several of the most advanced prototyping and machining centers available to be able to fabricate nearly anything. But to operate the equipment to produce successful prototypes, it takes our staff of experienced machinists, model makers, and engineers. Custom parts for varieties of industries are designed, developed, and fabricated for anyone from campus researchers to private sector goliaths to independent entrepreneurs. Development efficiency is achieved from combining the unique capabilities of each machining center to best carry out the fabrication of components. Iterations of highly-complex designs are streamlined due to the rare integration of engineering and CNC machining centers being just steps away to provide a cost-effective means of achieving success quickly.

We have developed and fabricated parts from surgical implants to auto body panels and we welcome your ideas. Please contact us to set up a visit and to discuss how we can collaborate to bring your idea to reality.

Prototype Design and Verification

Laser Scanning and CMM can map physical complex shapes and translate into electronic CAD models—including complex contoured surfaces—to enable design, quality assurance, and rapid prototyping using 3D printing and machining. We can also reverse engineer parts brought to us to generate CAD models. The scanner can also generate inspection data reports of dimensional accuracy on parts relative to native CAD.

Equipment

- Faro Arm and Laser Scanner provides a portable system for mapping the profile of any 3-dimensional object to allow initial CAD baseline models, reverse engineering, dimensional verification, and quality control of manufactured parts.

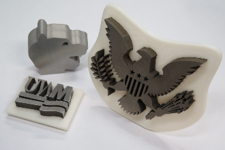

Rapid Prototype Fabrication

3D Printing—FDM uses fused deposition modeling to create parts through additive manufacturing and high-strength biocompatible plastics suitable for tools, toys, housings, mock-ups, ergonomic braces, medical device and dental prototypes capable of making any shape you can think up. There are few limitations on the end result of printed parts: casting in foundries, vacuum formed tools, chrome-plated auto parts, models from CT scans of bones, functional production parts, embedded hardware, autoclavable medical devices…etc…

Equipment

- Stratasys Fortus 400mc FDM 3D Printer uses additive manufacturing with production grade, high performance thermoplastics.

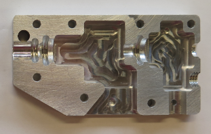

CNC Machining uses computer-controlled software to operate the articulating bed or machining head relative to a material to remove material to fabricate precise geometry of machinable surfaces. CAM-driven software will generate code to operate the machines to cut almost any ferrous or non-ferrous metal, plastic, or other material quickly and with great accuracy.

Equipment

- CNC 5-Axis Endmill can create nearly any contoured feature and pushes the envelope for what is now manufacturable. This machining center allows for non-conventional shapes to be precisely fabricated where it was once impossible with a 3-axis machine.

- CNC 3-Axis Vertical Endmill will fabricate shapes and parts that a conventional endmill will cut, but quickly, precisely, and repeatably in a controlled environment with flooded coolant for high-speed manufacturing.

- CNC Turning Center can create more than just cylindrically-spun types of shapes with its 4th axis live tooling to compliment conventional lathe functionality to reduce machines needed to create a part.

- CNC Router will make quick work when cutting through softer materials with 3D cutting capabilities for large parts to be made from woods, plastics, and foam prototypes..

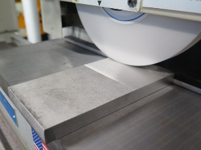

- 4-Axis Wire EDM will precisely cut through metallic material with an electrode-burning process to remove material to slice through thick or thin metals with very high quality surface finishes from the cut.

- CNC Plasma Cutter for quickly cutting through thick or thin metallic parts.

- Precision Linear Surface Grinder for high-surface quality flat finishes on planar surfaces held to incredibly tight tolerances.

Welding and Fabrication allows for manual welding of steels, stainless steels, titanium, and aluminum

Material Choices

3D printing and machining can produce nearly anything from cost-effective development models to functional production-quality parts.

Available Machining Materials

- Metals—steels (stainless or ferrous, various alloys), aluminums (various alloys), titaniums, and others.

- Plastics—thermoplastics and engineered plastics suitable for machining, 3D printing, vacuum forming, injection molding, bending, and other techniques.

- Woods and Composites—small to large sizes of varieties of wood, foam, and REN and MDF cut manually or with the CNC router to make tooling or prototypes.

To place an order or for more information please contact:

Director

Prototyping Center

(414) 316-3081

jansson@uwm.edu

1225 Discovery Parkway, Suite 162

Wauwatosa, WI 53226