Before we humans can build structures on the moon that use concrete, we’ll need a recipe—one that accounts for materials available on site (from lunar rock) and notes precisely what must be added to this mineralogical mix.

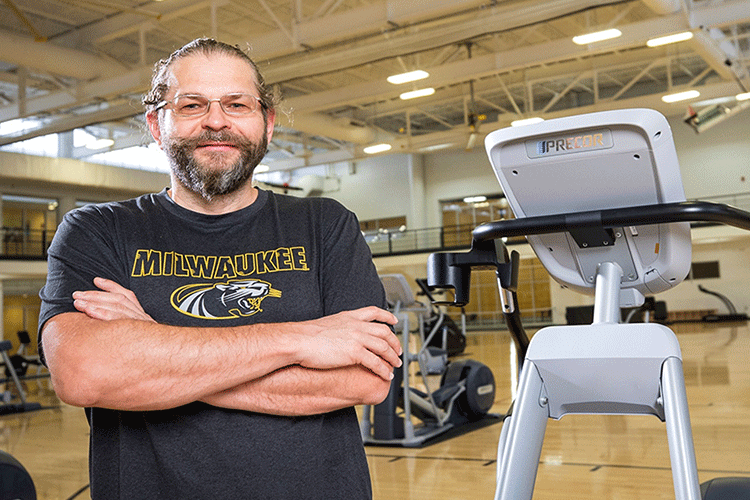

To that end, Konstantin Sobolev, professor, civil & environmental engineering, received a four-month, $30,000 grant in May from Utah-based Uplift Aerospace to characterize and analyze simulants of moon rock and formulate a concrete mix that could be used to create structures on the moon’s south pole.

Sobolev and his graduate students will work with two engineered simulants that mimic this lunar region’s regolith. Regolith is the collection of particles of dust, soil, broken rock and other materials that blanket terrestrial environments such as Earth, moons and asteroids.

The regolith composition is different for each surface, varying between celestial bodies and regions on each, and an ideal “recipe” for lunar concrete must be fine-tuned for each potential building site. A simulated regolith would open the door to planning and testing lunar concrete, without the expense of mining the moon’s surface and returning it to Earth.

According to Josh Hanes, Uplift Aerospace’s CEO, the company is developing a lunar regolith processing system with the goal of casting durable concrete structures on the moon.

Sobolev’s research, he says, will play a key role in selecting the binder and production methods needed to produce lunar concrete suited for the geography and temperature cycles of the moon’s south pole.