Training Certificate/Annual Review Form

I. PRINCIPLE

Many laboratory tests and procedures utilized in the Department of Biomedical Sciences result in the generation of biohazardous (infectious) waste. Biohazardous waste is any biological material that poses a potential risk to the health and well-being of humans, animals, or the environment. This policy defines what materials are considered biohazardous, along with proper disposal of these materials.

II. SCOPE

This policy applies to all students, non-students, and staff at the University of Wisconsin-Milwaukee that process biohazardous waste for disposal in the Department of Biomedical Sciences.

III. MATERIALS

Autoclave Bags, tape, buckets/pans

Diack steam cycle sterilization monitor

Heat safe gloves, vest, and face shield

BTSure AY759X1 Biological Test Ampules

IV. TRAINING

All staff and students that expect to process biohazardous waste for disposal must complete training by Lab Manager or PI, fill out Biohazardous Waste Disposal Training Certificate/Annual Review Form, with a submission type of “Initial Training Certification”, and complete all training required for operation of Autoclave SSR-3A-PB. After initial training, procedure must be reviewed annually and documented with the Training Certificate/Annual Review Form, submission type “Annual Procedure Review”.

V. PROCEDURE

The operator must wear Personal Protective Equipment (PPE), including face shield, thermal gloves, high heat vest, and proper lab attire when loading and unloading the chamber. Some materials, especially fluids, may cause severe burns to exposed skin.

A. OPERATION OF AUTOCLAVE

a. HOW TO RUN A CYCLE

i. Turn on the autoclave generator. A white power switch is located on the front lower right of the autoclave and will glow red when activated.

ii. Turn on exhaust fan. Switch is located on the wall opposite of the autoclave.

iii. Wait approximately 30 minutes to reach full jacket pressure (18±4 psi). Jacket pressure gauge is located on front lower left of the autoclave.

iv. Wearing heat resistant gloves and PPE (gloves and lab coat), load items into sterilizer as follows:

1. For biohazard bags, place in bin, making sure the bag is not overfilled or hanging over edges to avoid spilling of contents into autoclave. Bags should be loosely tied with twist tie and never knotted or closed tightly with tape.

a. Bags that are knotted or closed tightly do not allow steam to penetrate, resulting in improper sterilization and possible explosion of bag in autoclave.

2. For tubes and bottles, place in bin or tray. Loosen all caps or remove caps and cover with aluminum foil.

3. For sharps and needle boxes, close top securely and place in designated hazardous waste pickup area. University Safety & Assurances does not require autoclaving of these items prior to pick up.

NOTE: IT IS CRITICAL THAT ALL CAPS AND CLOSURES ARE LOOSE TO AVOID EXPLOSIO AND CRUSHING OF ITEMS IN AUTOCLAVE. ALL ITEMS MUST ALSO BE PLACED IN BINS AND PANSTO PREVENT SPILLAGE OF CONTENTS IN AUTOCLAVE.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY LEAD TO SERIOUS INJURY AND/OR DAMAGE TO THE AUTOCLAVE.

v. Attach Diack steam cycle sterilization monitor to an item in autoclave to be sterilized. Monitor may be taped to the outside of a biohazard bag with autoclave tape or tied around rack. One monitor is required for every sterilization cycle.

vi. Close the door to the sterilizer and turn the wheel clockwise to tighten.

vii. Set temperature recording disk to record immediately after previous run. Label run with date and initials. If recording disk is full, follow instructions on setting and changing recording disk located in section E of policy Autoclave SSR3ABP Use and Operation [EQUIP 1.0].

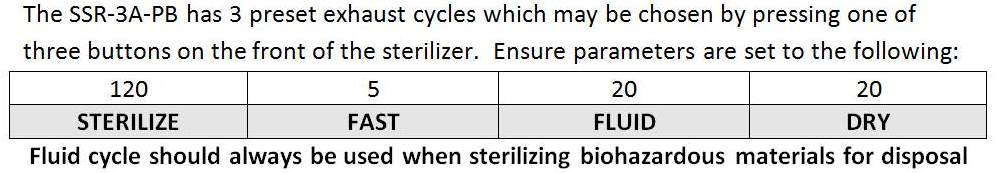

viii. Choose the fluid cycle and press red ON/OFF button to begin cycle.

ix. Complete Consolidated Sterilizer Log for model SSR-3A-PB.

b. HOW TO REMOVE A LOAD

x. Upon completion of a cycle, the chamber pressure will drop to ≤ 2 psi. At this point, press red ON/OFF button to end cycle.

xi. Turn the wheel counter clockwise and open door slowly, being careful not to get hot steam near face or unprotected skin (face shields should be worn when opening hot autoclave). Allow autoclave to cool for at least 10 minutes prior to unloading.

xii. Check the DIACK sterilization monitor for using of the clay to the glass tube and record on Consolidated Sterilizer Log (Fusing of clay indicates proper temperature was reached for adequate sterilization).

xiii. Turn on DYMO digital scale by pressing the power button. Place blue bin lined with a black garbage bag on top of scale, and press TARE button to set scale at 0.0.

a. Blue bin is labeled “Autoclaved Items Only”.

xiv. Wearing proper PPE (listed above), remove the load and place in the blue bin lined with a black garbage bag. Record weight on Consolidated Sterilizer Log.

xv. Once cool, garbage bag containing sterilized material may be closed and disposed of with normal trash.

xvi. If running multiple cycles in succession, steps (i-iii) only have to be performed for the first cycle. Steps (iv-xiii) must be performed for all cycles.

xvii. When all cycles are complete, turn off autoclave generator by pressing the white power switch on the front lower right of the sterilizer. Be careful to avoid the pressurized steam that is released when unit is turned off (Steam is released into an exhaust pipe located on the side of the autoclave).

xiv. Wearing proper PPE (listed above), remove the load and place in the blue bin lined with a black garbage bag. Record weight on Consolidated Sterilizer Log.

xv. Once cool, garbage bag containing sterilized material may be closed and disposed of with normal trash.

xvi. If running multiple cycles in succession, steps (i-iii) only have to be performed for the first cycle. Steps (iv-xiii) must be performed for all cycles.

xvii. When all cycles are complete, turn off autoclave generator by pressing the white power switch on the front lower right of the sterilizer. Be careful to avoid the pressurized steam that is released when unit is turned off (Steam is released into an exhaust pipe located on the side of the autoclave).

a. DYMO scale should be picked up off of floor prior to turning off sterilizer in order to avoid getting wet.

VI. QUALITY CONTROL

Steam sterilizers used for disposal of biohazardous and medical waste must be tested at least every 100 hours of use to satisfy DNR medical waste disposal guidelines.

Prior to testing, VWR incubator located in Enderis B90 must be adjusted to 56°C and allowed to come to temperature (may take over night).

A. Remove 3 BTSure units from box and identify the indicators by labeling two as “test” and one as “control” along with the date and initials.

B. Place the two “test” BTSure biological indicators in a horizontal position with materials to be sterilized. These should be placed in the “worst case” locations, in which the least lethal dose of heat and steam can reach the test ampules.

a. For example, one ampule could be placed in bin, and one could be placed inside of a larger biohazard bag.

C. Select the fluid cycle and process the load as usual. See section VI for use and operation of steam sterilizer. All Biohazardous waste must be sterilized for 120min at 254±4°F.

D. Once the sterilization cycle is complete, allow to cool for 10 minutes or more.

CAUTION: Failure to cool at least 10 minutes may cause the glass ampule to burst and may result in injury from hot liquid and/or flying debris.

E. Check the chemical indicator on the label for color change from blue to black. If the color does not change, repeat the sterilization cycle. If the color change does not occur a second time, it must be assumed that the sterilization has failed. Fill out action log and notify lab manager immediately.

F. Incubate the BTSure indicator at 55-60°C by utilizing the following steps.

a. To activate, place the indicator in an upright position in a plastic crusher. Gently squeeze the crusher to break the glass ampule.

b. At the same time, also incubate the non-sterilized “control” indicator ampule. Follow step above (a) to activate this ampule as well.

c. Place test and control ampules in incubator and incubate for 48 hours.

G. Examine the biological indicators for ANY color change

POSITIVE = Yellow color indicates bacterial growth (i.e. the control should turn yellow).

NEGATIVE = Purple color or no color change indicates adequate sterilization cycle.

H. Record the results on the Consolidated Sterilization Log as “pass” or “fail” based on the following:

EXPECTED RESULTS

Test ampule should be negative (purple color)

Control ampule should be positive (yellow color)

I. Dispose the used biological indicator ampules in the biohazard waste containers.

VII. BIOHAZARDOUS WASTE CATEGORIES

A. A solid waste which is included in any of the following categories is presumed to be infectious waste unless methods of testing which are generally accepted by the medical profession demonstrate that the waste is non-infectious:

a. Sharps, as follows:

i. Contaminated sharps which are both infectious and may easily cause punctures or cuts in the skin, including but not limited to: hypodermic needles, syringes with needles attached, scalpel blades, lancets, broken glass vials, broken rigid plastic vials and laboratory slides.

ii. Unused or disinfected sharps which are being discarded, including hypodermic needles, scalpel blades, lancets and syringes with needles attached.

b. Bulk blood and body fluids from humans.

c. Human tissue.

d. Microbiological laboratory waste.

e. Tissue, bulk blood or body fluids from an animal which is carrying a zoonotic infectious agent.

B. A solid waste which is not included in the definition of infectious waste, which is not mixed with infectious waste and which does not fall under one of the A solid waste which is not included in the definition of infectious waste, which is not mixed with infectious waste and which does not fall under one of the categories in section (a) is presumed not to be an infectious waste. Solid wastes presumed not to be infectious wastes include all of the following:

a. Items soiled but not saturated with blood or body fluids from humans.

b. Intravenous tubing after needles have been detached.

c. Tissue, blood, body fluids or cultures from an animal which is not known to be carrying or experimentally infected with a zoonotic infectious agent.

d. Animal manure and bedding.

e. Other solid wastes, including but not limited to containers, packages, waste glass, laboratory equipment and other materials which have had no contact with blood, body fluids, clinical cultures or infectious agents. When possible, use of these items shall be reduced, and the items shall be reused or recycled.

f. Formerly infectious waste, after it has been treated according to section IX(A-B) in this procedure, or has been treated according to Wisconsin administrative code section NR 526.11 of Chapter NR 526 Medical Waste Management.

VIII. REFERENCES

Operating and Maintenance manual for the Consolidated Model SSR-3A-PB, serial #41285 Electrically Heated Sterilizer

BTSure Biological Indicator product insert. Thermo Fisher Scientific, Marietta, OH. – Rev. 16

Wisconsin Department of Natural Resources Administrative Codes Chapter NR 526 “Medical Waste Management”. Register, January, 2006, No. 601.

IX. PROCEDCURAL NOTES

a. The containers of infectious waste shall be removed and emptied as necessary, but at least every 90 days.

b. No person may mix infectious waste in the same bag or waste receptacle with solid waste which is not infectious waste, unless mixing the wastes is necessary to protect the health or safety of students, employees or other persons.

c. No person may separate infectious waste from solid waste which is not infectious waste unless adequate measures are taken to protect waste handlers and other persons from exposure. After separation, solid waste previously mixed in the same bag or waste receptacle with infectious waste shall be managed as infectious waste.

d. No person may remove solid waste and infectious waste that has been placed in a bag or waste container labeled with the biohazard symbol or fail to manage the waste as infectious waste from the time of generation until the waste has been treated according to section V of this procedure, or has been treated according to s. NR 526.11 of the Wisconsin administrative code, unless the person follows waste management procedures which will protect waste handlers and other persons from exposure.

X. ATTACHMENTS

Consolidated Sterilizer Log [SAFE 2.0.A]

Biohazardous Waste Disposal Training Certification Log [SAFE 2.0.B] PDF

Reviewed: 8/9/2016, 8/21/2017, 8/10/2018, 8/6/2019