A win-wind proposition

High wind gusts – the very reason wind turbines can crank out energy – also cause severe vibrations that can crack the blades. That poses unpredictable safety hazards, and replacing even one blade carries a hefty price tag.

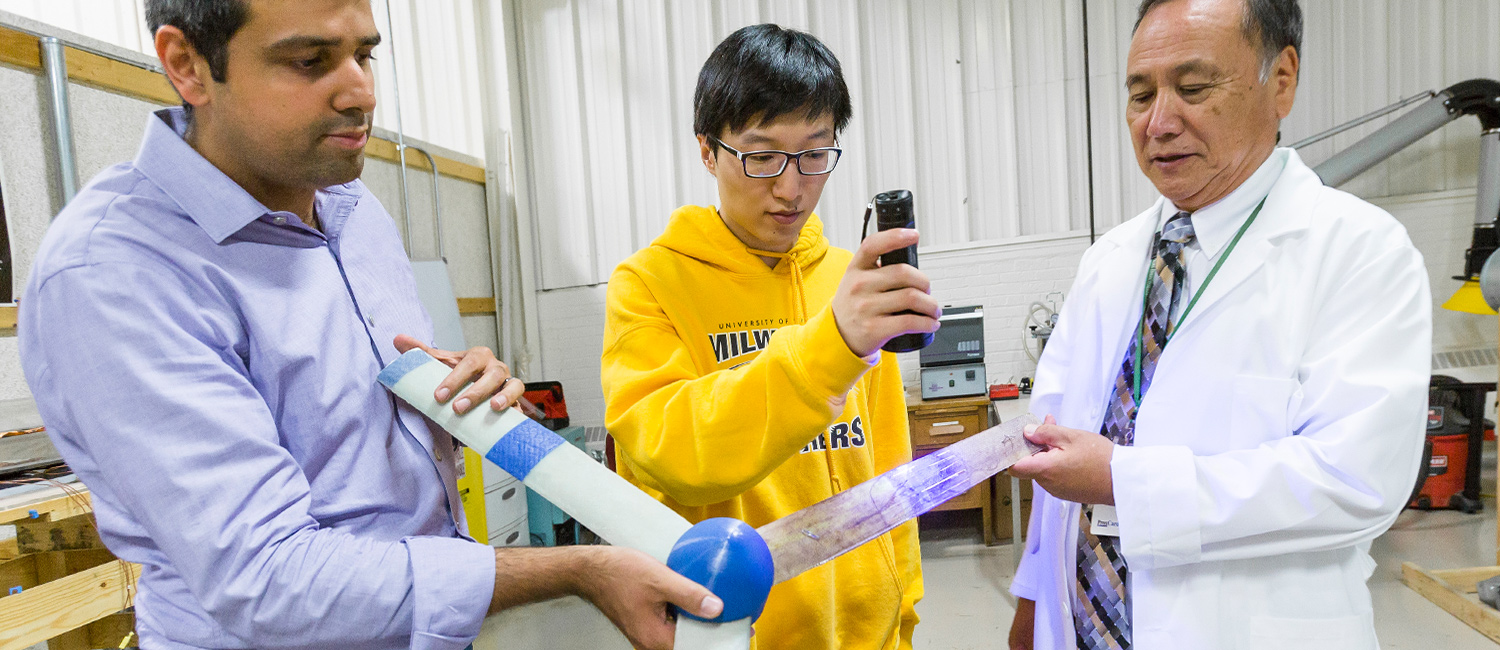

One possible solution? Blades that heal themselves. UWM mechanical engineering professor Ryo Amano and a former graduate student created a material that does just that. “Like blood clotting,” Amano says.

Inside each hollow blade, which is made of polymer and fiberglass composites, Amano and Arun Kumar Koralagundi Matt insert short lengths of hair-like glass tubing. They contain a liquid healing agent surrounded by a hardened blend of epoxy resin and a special catalyst powder.

When a crack forms on the blade’s surface, it breaks the delicate tubing, which releases the healing agent that seeps into the crack. That reacts with the surrounding catalyst to create a kind of solder that solidifies in a matter of hours.

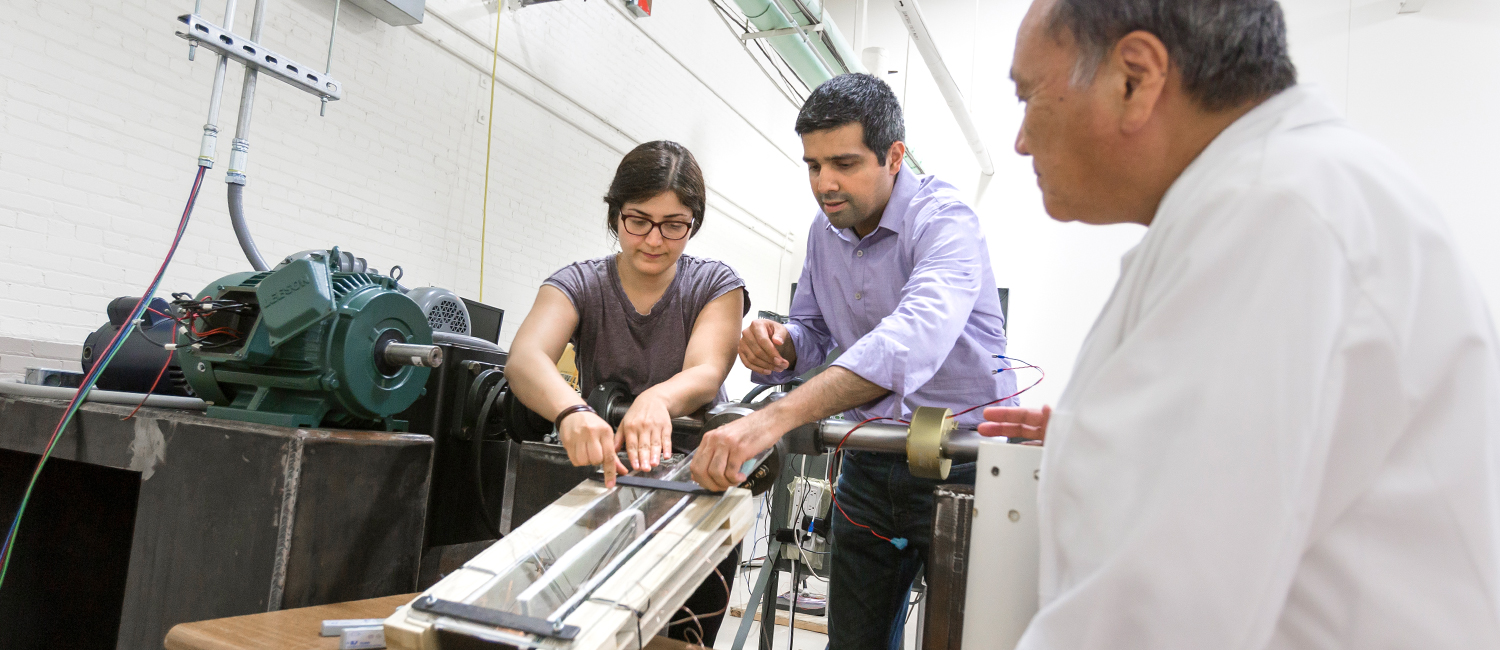

Successful tests of the concept were performed inside UWM’s experimental wind tunnel, the state’s largest such facility and one of the country’s largest, too. Amano says the method can add several years to the lifespan of blades.