Training Certificate/Annual Review Form

I. PRINCIPLE

Liquid nitrogen is a colorless, odorless, tasteless liquid, with a boiling point of -195.79 °C (-320 °F). Liquid nitrogen can cause rapid freezing on contact with living tissue, and can result in serious injuries if exposed to the skin or eyes. Beyond injury through contact exposure, rapid boiling of liquid results in nitrogen gas production. Liquid nitrogen expands at a ratio of 1:694 at 20 degrees Celsius, and can lead to explosion if handled improperly. Nitrogen gas is lighter than room air, and can cause asphyxiation if oxygen levels are reduced below 21%.

II. SCOPE

This procedure applies to all students and staff that use liquid nitrogen in the University of Wisconsin – Milwaukee College of Health Professions & Sciences, Department of Biomedical Sciences.

III. TRAINING

All staff and students that expect to work with liquid nitrogen must review this procedure, complete training by Lab Manager or PI, and fill out the Liquid Nitrogen Handling Procedure Training Certificate/Annual Review Form, with a submission type of “Initial Training Certification”. After initial training, procedure must be reviewed annually and documented with the Training Certificate/Annual Review Form, submission type “Annual Procedure Review”.

IV. PROCEDURE

A. Industrial grade liquid nitrogen is delivered from the supplier stored in a 230 liter cylinder (22PSI). Liquid nitrogen shall only be dispensed from this storage device with the appropriate cryogenic hose and phase separator properly connected to the container.

B. Cylinders should be stored upright, with valve protection cap in place, and firmly secured to prevent falling or being knocked over. Cylinder temperatures should not exceed 52 degrees Celsius (125 degrees Fahrenheit).

C. The area in which the cylinder and long term storage dewer is kept must be adequately ventilated.

a. Walk-in cold rooms are typically poorly ventilated and shall not be used to store liquid nitrogen.

b. Refrigerators and freezers pose the additional risk of explosion due to expansion of gas, and shall not be used to store liquid nitrogen.

D. Liquid nitrogen may only be dispensed into a Dewar flask (for long term storage) or approved small volume cryogenic storage container (for short term use). If there is uncertainty regarding the storage container, contact the lab manager for consultation.

a. Due to the high boiling point of liquid nitrogen, splashing always occurs when filling a warm container with cryogenic liquid or when inserting objects into this liquid. Proper personal protective equipment shall be worn at all times when handling this liquid. Due to the rapid expansion when exposed to warm temperatures, pipettes and other hollow tubes have the potential to squirt liquid, and should never be used to transfer liquid nitrogen.

b. A cryogenic phase separator must always be used when transferring N2 from the primary cylinder. This item screws on to the end of the cryogenic transfer hose, and reduces splashing by eliminating air inside of the hose. If damaged, reorder item Y15PSB38 from AIRGAS.

i. Ensure Phase Separator is inside of secondary container when filling

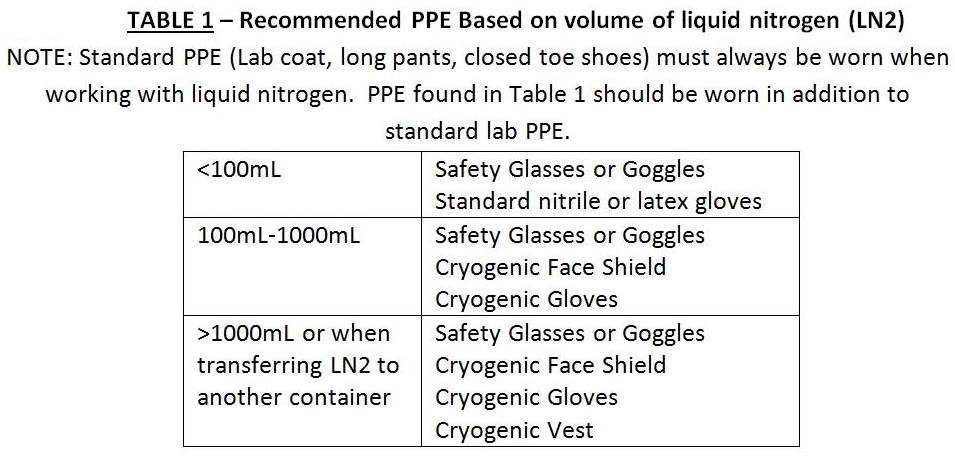

E. Engineering controls and personal protective equipment (PPE) must be used when handling all cryogenic materials. Personal protective equipment should be selected based on the task being performed and the risks involved (see Table 1). Use only with adequate ventilation.

F. Objects removed from liquid nitrogen may explode during thawing, and caution should be taken during the thawing process. Eye protection and PPE should be worn when working with these items.

a. It is recommended that items are placed behind a protective glass shield or inside of a closed biohazard or fume hood while thawing. Exploding containers and tubes may cause injury.

G. Disposal of unused liquid nitrogen is through evaporation in a well-vented area.

a. Do not dispose of any unused liquid nitrogen in any waste container.

b. Never pour liquid nitrogen down a sink drain. The piping material is not designed for cryogenic temperatures and can fracture.

V. FIRST AID

A. If any emergency situation arises from a large volume spill or serious injury, immediately institute emergency response protocols by dialing 9911 from any campus phone, or (414)229-9911 from any cellular phone.

No action shall be taken involving any personal risk or without suitable training. If it is suspected that fumes are still present, the rescuer should wear an appropriate mask or self-contained breathing apparatus. It may be dangerous to the person providing aid to give mouth-to-mouth resuscitation.

B. Skin Contact – The tissue should be restored to normal body temperature by running warm liquid (108 degrees F) over the affected part. The affected part should not be rubbed at any time, as this will cause further damage to the area. The victim should get emergency care as quickly as possible to minimize further damage and for damage assessment.

C. Eye Contact – Check for and remove any contact lenses. Immediately flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical attention immediately.

D. Inhalation – Move exposed person to fresh air. If not breathing, if breathing is irregular or if respiratory arrest occurs, provide artificial respiration or oxygen by trained personnel. Loosen tight clothing such as a collar, tie, belt or waistband. Get medical attention immediately.

VI. REFERENCES

Liquid Nitrogen Material Safety Data Sheet, Airgas, Revision Date 11/22/2013

Cryogenics, Safe Lab Practices and Procedures, Princeton University web site, 12 September 2014

Handling Liquid Nitrogen: Personal Protection, Massachusetts Institute of Technology, Chemical Research Safety Note #12, 12 September 2014

Laboratory Safety: Cryogens and Dry Ice, OSHA, OSHA Quick Facts, 12 September 2014

VII. PROCEDURAL NOTES

A. Substances may become brittle upon contact with liquid nitrogen.

VIII. Attachments

Liquid Nitrogen Handling Procedure Training Certification Log [SAFE 1.0.A] PDF

Reviewed: 8/9/2016, 8/21/2017, 8/10/2018, 8/6/2019, 5/4/2023